Wind power slip ring

2024-06-12 16:58:20A slip ring, also known as a rotary electrical joint, is a device used to transmit electrical power and signals from a stationary structure to a rotating one. In the context of wind power, slip rings are commonly used in wind turbines to transfer electrical power and signals between the stationary components (such as the tower) and the rotating components (such as the blades and the generator).

In a wind turbine, the blades are mounted on a rotor that rotates with the wind, while the generator is a stationary component. The slip ring allows for the transfer of electrical power generated by the rotating blades to the stationary generator, which then converts it into usable electricity.

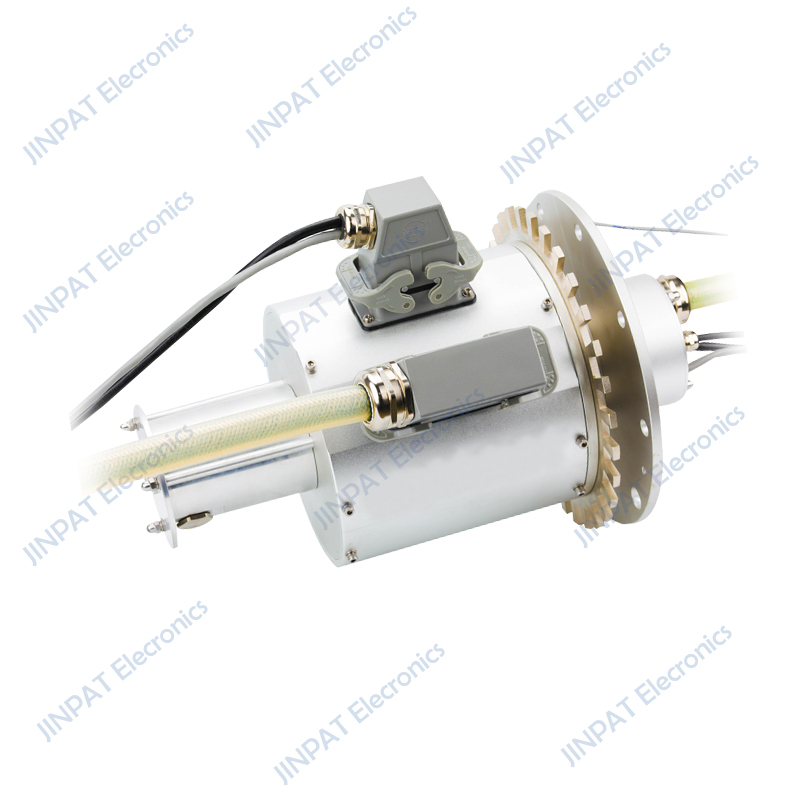

The slip ring assembly typically consists of two main parts: the stationary part, known as the stator, and the rotating part, known as the rotor. The stator is connected to the stationary structure, while the rotor is connected to the rotating component. The slip ring enables the electrical connection between these two parts through a set of brushes or contact points that maintain continuous electrical contact as the rotor rotates.

Wind power slip rings are designed to handle high currents and voltages, as well as transmit signals for control and monitoring purposes. They need to be durable, reliable, and capable of withstanding the harsh operating conditions experienced in wind turbines, such as high winds, vibrations, and temperature variations.

Slip rings used in wind turbines are typically made of robust materials such as stainless steel or aluminum, and they are often sealed to protect them from dust, moisture, and other environmental contaminants. Additionally, they may incorporate advanced features like self-lubrication systems or maintenance-free designs to ensure long-term performance and minimize maintenance requirements.

Overall, wind power slip rings play a crucial role in enabling the efficient and reliable transmission of electrical power and signals in wind turbines, contributing to the generation of renewable energy from wind sources.

JINPAT wind power slip ring: LPW-05-SPX(JP06-182-03) which is applied to Wind Power Generator, with the working Temperature -30°C—+60°C(Storage Temperature:-40°—+60°C),working Humidity 0~100%RH, and contact Material Copper Graphite/Precious,which make our product remarkably durable and compatible.