Signal slip ring

Designed for low electrical noise, minimal crosstalk, and long service life, JINPAT standard signal slip rings support reliable data integrity and flexible customization for demanding industrial applications.

Designed for low electrical noise, minimal crosstalk, and long service life, JINPAT standard signal slip rings support reliable data integrity and flexible customization for demanding industrial applications.

Standard electrical slip rings for stable power and signal transmission in rotating industrial equipment. Modular design, reliable performance, suitable for automation and robotics.

RF and fiber optic rotary joints are precision electromechanical components that enable continuous, low-loss transmission of high-frequency RF signals and optical data across a rotating interface.

Pneumatic and hydraulic rotary joints for continuous air, oil and fluid transfer in rotating systems. Leak-resistant design, long service life, and application-specific customization.

High current slip rings designed for stable power transmission under high load conditions. Supporting multi-circuit, high-amperage operation for demanding industrial applications.

Custom slip rings and rotary joints engineered to meet specific application requirements. Electrical, signal, fiber optic, and fluid integration supported by JINPAT engineering expertise.

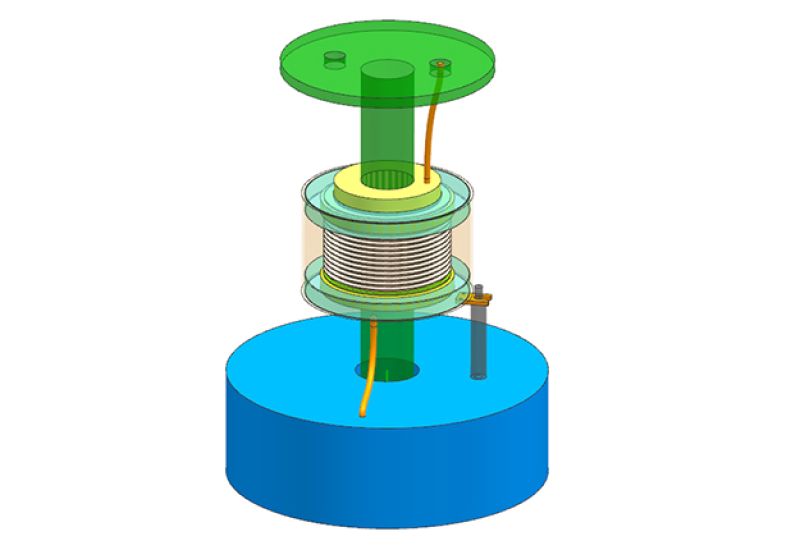

A slip ring, also known as a rotary electrical joint, is an electromechanical device that enables the transmission of electrical power, signals, or data between stationary and rotating parts.

A typical slip ring consists of two main components:

Rotor – mounted on the rotating structure

Stator – fixed to the stationary structure

By maintaining continuous electrical contact during rotation, slip rings allow systems to rotate freely without cable twisting or signal interruption.

A slip ring operates through conductive rings attached to the rotor and stationary brushes mounted on the stator. As the rotor rotates, the brushes maintain constant contact with the conductive rings, enabling uninterrupted transmission of power or signals across the rotating interface.

JINPAT slip rings are engineered with optimized contact materials and precision structures to ensure low electrical noise, stable transmission, and long-term operational reliability—even in continuous or high-speed rotation environments.

Slip rings are manufactured using carefully selected materials based on performance and environmental requirements:

Conductive Rings: Copper, brass, or specialized conductive alloys for stable conductivity

Brushes: Carbon-graphite or precious metal composites for low wear and reliable contact

Housings & Structures: Aluminum, stainless steel, or engineered metals for mechanical strength, heat dissipation, and corrosion resistance

Material selection directly affects electrical performance, lifespan, and suitability for harsh environments.

Slip rings are used in systems that require continuous rotation while transmitting power or signals. Typical applications include industrial automation, robotics, new energy systems, marine equipment, engineering machinery, medical devices, aerospace, defense systems, and advanced test equipment.

JINPAT specializes in designing slip rings for applications with demanding requirements on stability, precision, and durability.

The service life of a slip ring depends on factors such as design, materials, operating speed, load conditions, and maintenance practices.

Most JINPAT slip rings are engineered for long-term operation, with many models exceeding 200 million rotations under proper working conditions—making them suitable for continuous-duty industrial applications.

Please leave your message and we will contact you as soon as possible!

With nearly 30 years of focused R&D in slip ring technology, JINPAT has developed a wide range of rotating transmission solutions—from proven standard models to fully customized designs for complex applications. We understand that no two systems are the same. Electrical parameters, mechanical constraints, environmental conditions, and integration requirements all vary by application. Our engineering team works directly with customers to define these factors and design slip rings that deliver stable performance, long service life, and seamless integration into real operating environments. From concept validation to mass production, JINPAT provides reliable custom slip ring solutions that support power, signal, fiber optic, and fluid transmission—helping customers solve demanding rotating challenges with confidence.

JINPAT slip rings are widely used across industries that require reliable power and signal transmission under continuous rotation. Our products support applications in industrial automation, robotics, medical equipment, consumer electronics, engineering machinery, offshore and marine systems, and other demanding industrial environments. By adapting electrical configurations, mechanical structures, and protection levels, JINPAT slip rings are designed to meet the performance and reliability requirements of diverse industries worldwide.