The Application of Slip Rings in Mechanical Laser Radar

2024-05-29 11:30:42Mechanical laser radar is a widely used sensor technology for distance measurement, 3D modeling, and environmental sensing. Their operation involves the emission and reception of laser beams,often requiring rotating components to scan the surrounding environment. To achieve continuous rotation and transmit power and data signals, mechanical laser radar typically relies on electric slip rings or optical fiber slip rings to support the transmission of power signals.

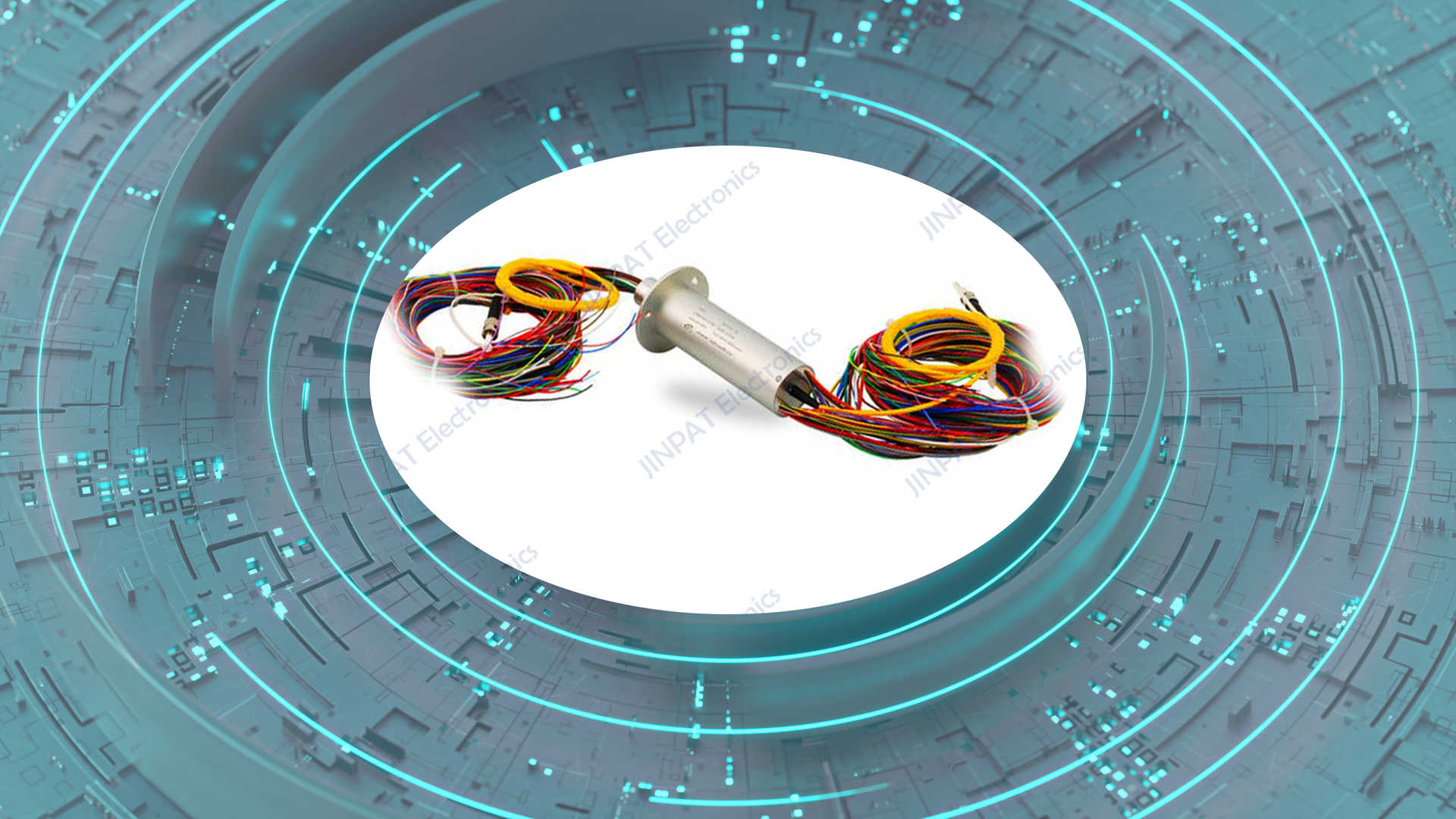

One notable feature of many laser radars on the market is that their operating wavelengths align with the optical signal bands that optical fiber slip rings can transmit. This makes solving the signal transmission problem for mechanical laser radar relatively straightforward. For instance, most optical fiber slip rings developed by JINPAT support operating wavelengths ranging from 650 nanometers to 1650 nanometers, with only a few models operating within the 850 nanometers to 1550 nanometers range. These bands cover almost all mainstream laser radar operating wavelength ranges.Additionally, JINPAT developed optical fiber slip rings possess excellent electrical characteristics and must be capable of transmitting high current and high-frequency signals to meet the power supply and data transmission requirements of laser radar.

For mechanical laser radar, the generated data volume is relatively small, and there is no need to transmit data over long distances. Since mechanical laser radar typically requires continuous operation for extended periods, slip rings must have high durability and stability to minimize maintenance needs. Therefore, using single-channel multi mode optical fiber slip rings can effectively address the issue of laser radar signal transmission. This approach has two distinct advantages: one is better alignment with the working wavelength range of laser radar, and the other is that optical fiber slip rings have an extremely long lifespan, capable of enduring hundreds of millions of rotations, fully meeting the long-termmaintenance-free requirements of laser radar.

Once the signal transmission issue is resolved through optical fiber slip rings, the electrical transmission problem becomes simpler. The mechanical design of the slip rings must align with the mechanical structure of the laser radar to ensure stability during installation and connection. A reasonable mechanical design helps reduce friction and wear,extending the lifespan of the slip rings. Using traditional electro-optical integrated slip rings may result in insufficient lifespan and could increase the volume of the laser radar, affecting its stability. In terms of rotary conductive solutions, as a specialized slip ring manufacturer, JINPAT provides wireless coil power supply solutions.

In conclusion, selecting the appropriate slip rings for mechanical laser radar depends on the specific requirements of the radar. Different models and manufacturers of laser radar may require different types of slip rings to ensure their performance and reliability.Therefore, the choice of slip rings should be made based on a comprehensive consideration of these factors. Feel free to consult JINPAT, and we will provide high-quality solutions.