What is a slip ring?

A slip ring, also known as a rotary electrical interface, collector, swivel, or rotary joint, is an electromechanical device that allows the transmission of power and electrical signals from a stationary to a rotating structure. It is commonly used in applications where a continuous rotation is required while maintaining an electrical connection, such as in wind turbines, robotics, medical equipment, and various industrial machinery.

Slip rings enhance mechanical performance, simplify system operation, and eliminate damage-prone wires dangling from movable joints. They are essential for any system where electrical components need to rotate freely without the limitations and wear of traditional wiring methods. With advancements in technology, slip rings now come in various configurations and materials, offering solutions for a wide range of electrical and signal transmission requirements.

At JINPAT, we specialize in designing and manufacturing high-quality slip rings tailored to meet the unique needs of our customers, ensuring reliable performance and durability in even the most demanding applications.

A slip ring, also known as a rotary electrical joint, is a mechanical device used to transmit electrical signals, power, or data from a stationary structure to a rotating one. It's commonly employed in applications where continuous rotation is required while maintaining electrical connections between components or systems.

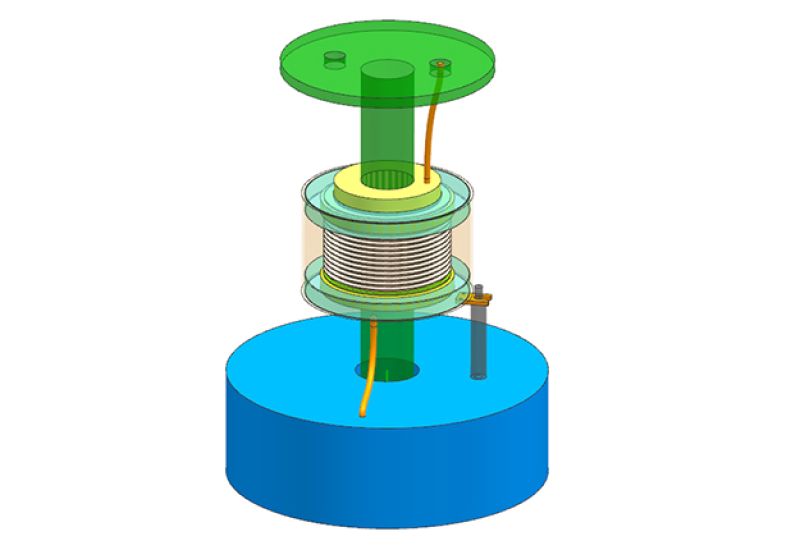

The slip ring consists of two main components: a stationary part called the "stator" and a rotating part called the "rotor." These components are in direct contact with each other and allow the transfer of electrical signals or power between them. The stator is typically mounted to a fixed structure, while the rotor is attached to the rotating component.

A slip ring works by enabling the transfer of electrical signals, power, or data from a stationary structure to a rotating one. It consists of conductive rings mounted on the rotating part (rotor) and stationary brushes mounted on the stationary part (stator). As the rotor turns, the brushes maintain constant contact with the rings, allowing electrical connections to be maintained while enabling continuous rotation. This enables the transmission of signals or power between the stationary and rotating parts.

Crafted with precision and innovation, JINPAT slip rings boast a remarkable fusion of high-quality materials and cutting-edge design. Unlock a world of superior performance and uninterrupted connectivity for your rotating systems.

Slip rings are typically made using various materials, depending on the specific application, operating conditions, and desired performance characteristics. Some common materials used for slip rings include:

Conductive Rings: The rings themselves are often made of conductive materials such as copper, brass, or other metal alloys. These materials offer good electrical conductivity and durability.

Brushes:Carbon-graphite is a commonly used material for brushes due to its ability to maintain electrical contact while enduring friction.

Housings and Enclosures: The overall structure of the slip ring assembly may be constructed using materials like aluminum, stainless steel, or other metals for their strength and durability.

It's important to select materials that match the requirements of the specific application, considering factors such as electrical conductivity, wear resistance, thermal conductivity, corrosion resistance, and environmental conditions.

JINPAT is a leading high-tech enterprise specialized in slip ring design and manufacturing with its business scope covering industrial automation,robot, new energy, marine industry,engineering machinery, medical technology, consumer electronics, aerospace and defense and new rising industries with demanding requirements on slip ring.

The lifespan of slip rings can vary widely depending on several factors, including the quality of materials used, the design of the slip ring assembly, the operating conditions, maintenance practices, and the specific application. Generally, well-designed and properly maintained slip rings can last for a considerable amount of time.

Most slip rings of JINPAT have a lifespan exceeding 200 million rotations

Please leave your message and we will contact you as soon as possible!

At JINPAT, we pride ourselves on nearly 30 years of dedicated research and development in the slip ring industry. Our extensive experience has enabled us to develop countless slip ring solutions, ranging from standard models to highly customized products tailored to meet specific customer requirements. We understand that every application is unique, and we are committed to providing slip rings that perfectly fit your needs. Our expert team works closely with clients to design and manufacture slip rings that deliver reliable performance and durability, no matter how complex the demands. Choose JINPAT for innovative, custom slip ring solutions that ensure seamless electrical and signal transmission for your projects.

JINPAT slip rings are widely used in industries such as automation equipment, robots, medical equipment, consumer electronics, construction machinery, offshore equipment, and new energy equipment.